Value Added Design & Manufacturing

With more than 75 years of delivering high quality solutions and extraordinary services to our customers, we can bring your ideas to the next level.

Our mission is to empower your business with

our expertise from start to finish.

We understand the importance of having access to the right information and resources, so that you can make informed decisions about your products. With our tools and knowledge, we ensure the best possible outcome is achieved for your project. Here’s why we’re the best in the business:

- Improved efficiency and quality

- Reduced costs and lead times

- Increased production capability and flexibility

- Environmentally friendly with reduced material waste

- Top-of-the-line automation and rapid prototyping

- Customization to fit your specific needs

- Low-volume production and complex geometries with our 3D Printing technology

- On-demand manufacturing whenever you need it

Capabilities

In-House Research And Development

For over 75 years, our in-house research takes place at three main locations in North Carolina- West Jefferson, Belmont, and Charlotte. Our team comprised of standout engineers and designers work together to develop long-lasting, high-quality solutions.

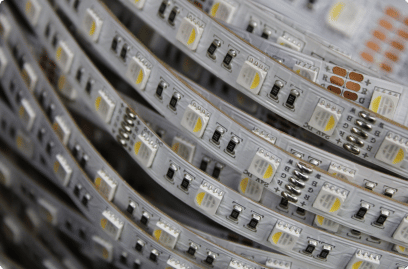

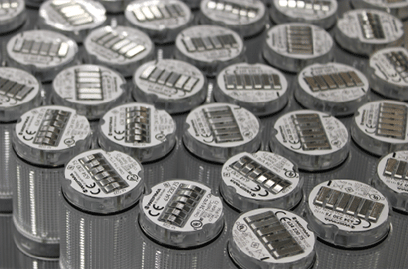

Cutting-Edge Components

At Kinequip providing the perfect blend of modern innovation and unbeatable quality is imperative, allowing customers to benefit from the latest technological advancements without sacrificing quality or cost.

Our Cutting Edge Components are top of the line developments for businesses looking to maximize productivity, efficiency, and durability at an affordable cost.

Specialty Made Parts

We understand that when it comes to building and constructing, having the right tools makes all the difference.

That is why we offer specialty made parts of exceptional quality that can be adapted to any project. Ourparts are extremely customizable, allowing for unique solutions tailored to every client’s needs.

We offer expert advice and assistance when it

comes to selecting the right parts for your

build at any step of the process.

Process

The Kinequips Design and Approval Process guarantees top quality, customer satisfaction driven products.

It starts with a concept pitch, where customers give input that drives the research and development of advanced prototypes.

After approval is granted, each product goes into manufacturing followed by comprehensive testing to make sure every detail meets the customer specifications before the final product is ready for distribution. Customer feedback plays a massive role at every stage in this process, ensuring that each product receives detailed attention and that it will meet all expectations when released to its intended market.

Concept

During this stage, the customer describes their need and meets with a knowledgeable representative from Kinequip. The representative offers their expertise and listens carefully to the customer in order to understand exactly what is required in terms of specific qualities and capabilities. With this information in hand, Kinequip can craft a solution that meets all customer needs.

The Research & Development stage of the Kinequip Design and Approval Process is a pivotal part of making a customer’s request come to life.

During this internal process, members of all different Kinequip departments come together to research and develop the best version of their idea, as it takes the collective expertise of each group to make this possible. By putting minds together through this stage, Kinequip can create something unique that aims to exceed customer expectations.

As the Kinequip Design and Approval Process progresses, Stage 3 brings great anticipation; it is the moment where customers are shown the first physical representation of their vision.

This prototype is designed to emulate the desired design in order to provide an accurate assessment of what further adjustments can or should be made. It’s a vital step in the process and gives customers a chance to visualize all the hard work that went into making something unique for them.

Once the design has gone through stages 1-3 of the Kinequip Design and Approval Process, the customer is asked to approve it.

All adjustments made will be carefully assessed, making sure that they adhere to the standards set earlier on in the process, and meet all customer expectations. Once this has been done, the customer is given a chance to sign off on their product, giving them peace of mind knowing that every detail has already been tended to. This ensures that our customers’ degrees of satisfaction remain at an ideal level throughout every project we take on.

This stage is crucial for ensuring complete accuracy since real-world testing results follow the products from concept to completion. During this manufacturing process, each part is designed to address the exact specifications outlined by customers.

After a product has been manufactured, quality must be assessed to make sure the design specifications are being met and that the quality standards are being upheld. Before it is ready for use, Prototypes undergo rigorous testing procedures to make sure they meet quality, safety, performance, and durability standards before it’s ready for mass production. Testing can include tensile strength tests, fatigue testing, thermodynamic cycle testing and more. We do what it takes to ensure products exceed customer satisfaction

The finalized product is fully ready to ship to its customer and put into use, full of features designed to meet all their needs. From 3D modeling, through rendering and prototyping, this entire journey is defined by quality assurance testing and adherence to standards ensuring only the most reliable products for our customers. Through this rigorous process, Kinequip has forged a reputation for producing high-quality items with top-notch features that customers can trust.

Services

Design and Prototyping

Kinequip’s skilled engineering and design team offers a full suite of services. The flexibility to design and prototype new industrial machinery, mechanical products, and electrical components is our strongest attribute.

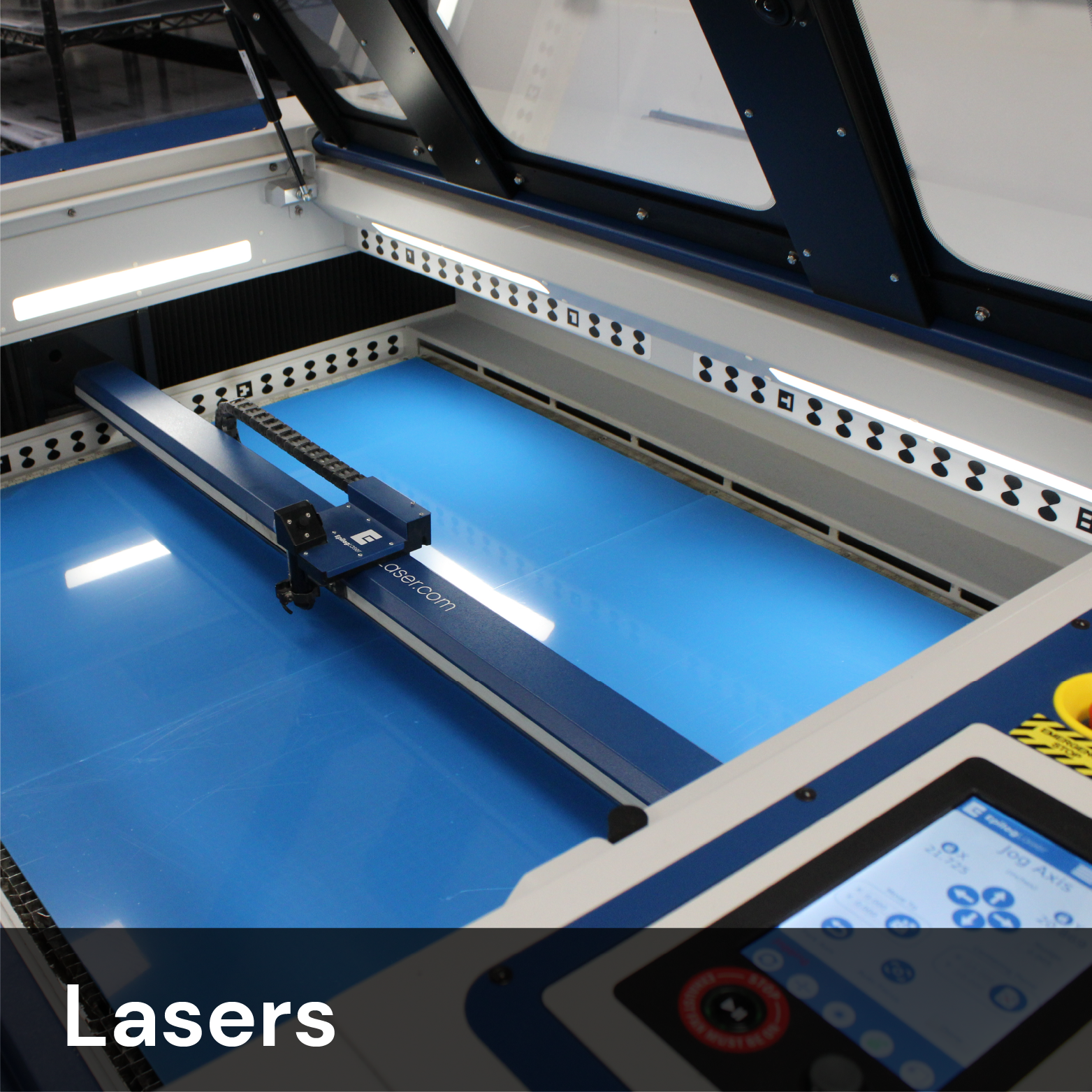

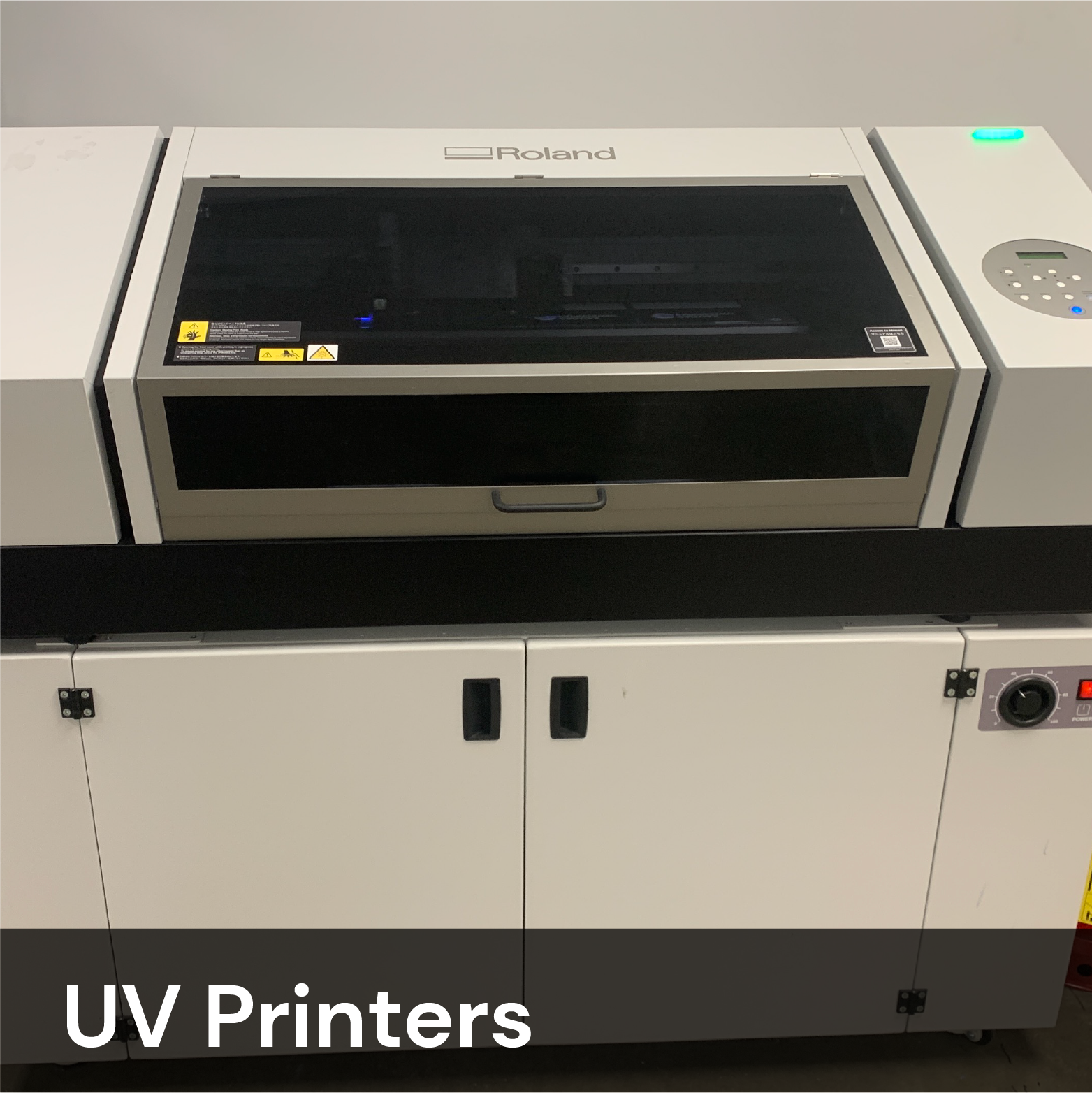

Mechanical and Electrical Engineering Services

From concept to delivery, Kinequip’s engineers design advanced electrical systems to provide turnkey solutions for any manufacturing need. Utilizing industry leading equipment including in-house 3D Printing, CNC Milling, Laser Cutting, and more, is equipped to handle the most custom requests.

In-House Testing and Production

The need for advanced component production and testing is a requirement in a modern manufacturing setting. Our team builds and tests projects in-house using state of the art equipment while verifying standards for product safety and build quality. We offer best-in-class technology and the most modern services in the industry.

Equipment

Using cutting-edge technology, optimized workflow designs and partnerships with top-tier manufacturers, Kinequip strives to continually push the envelope when it comes to providing superior products at the best possible price. Our selection of equipment is essential for achieving these goals and ensuring customer satisfaction time after time.

Want to Learn More?