SIHI Dry

Vacuum Pumps

Simple, Dry and Reliable

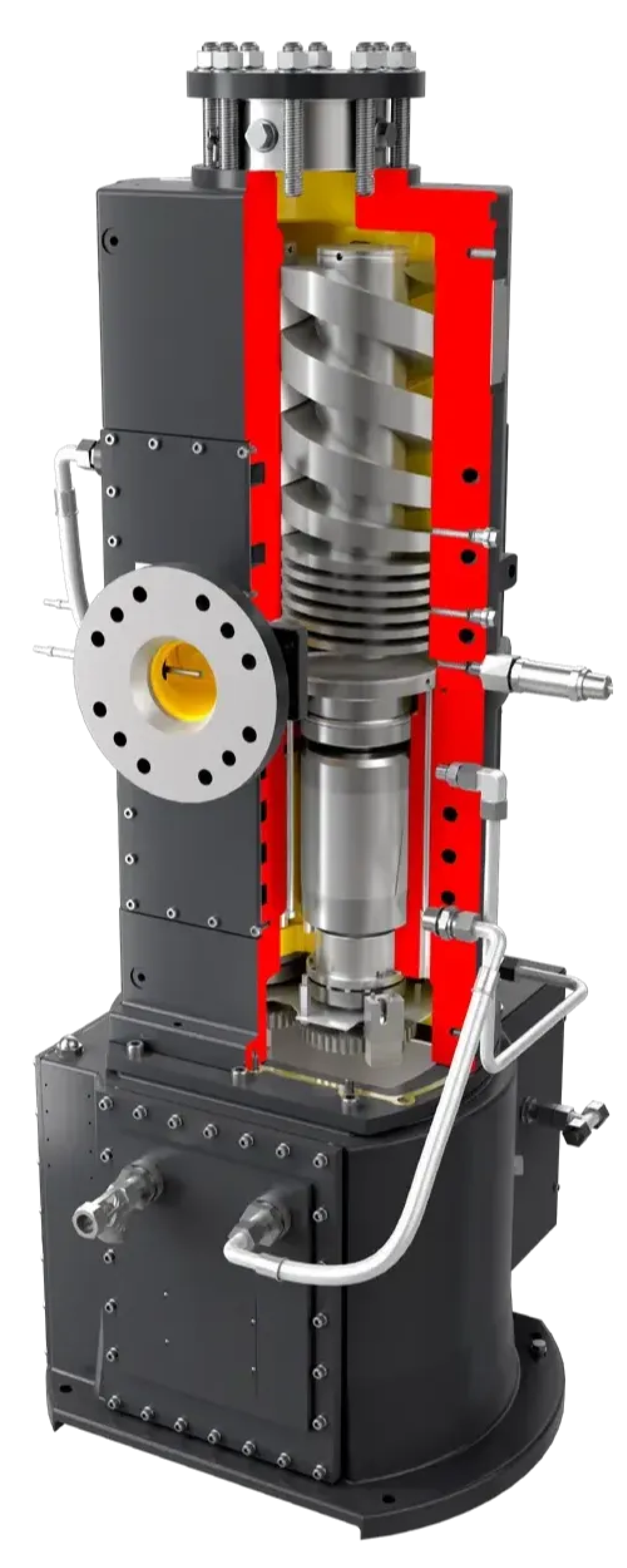

Introducing the SIHI® Dry pumps. Designed to be vertically oriented and self-draining, this pump is ideal for industrial processes where there is a high likelihood of liquids or solids being carried over into the pump.

The pump incorporates an intelligent drive system that conducts ongoing rotor diagnostics and provides an energy-efficient platform for controlling variable speed and pressure. Additionally, this rotor synchronization method allows for gearbox-free operation, ensuring quiet and lubrication-free performance. The SIHI® Dry design also includes continuous torque monitoring, automatically adjusting speed to accommodate liquid and solids carry-over.

Dry Running Vacuum Pumps for General Industries

The SIHI® Chemical PD vacuums are engineered specifically for industries with demand for oil and contamination free vacuum. These pumps operate at low pressures and have the flexibility for batch processes.

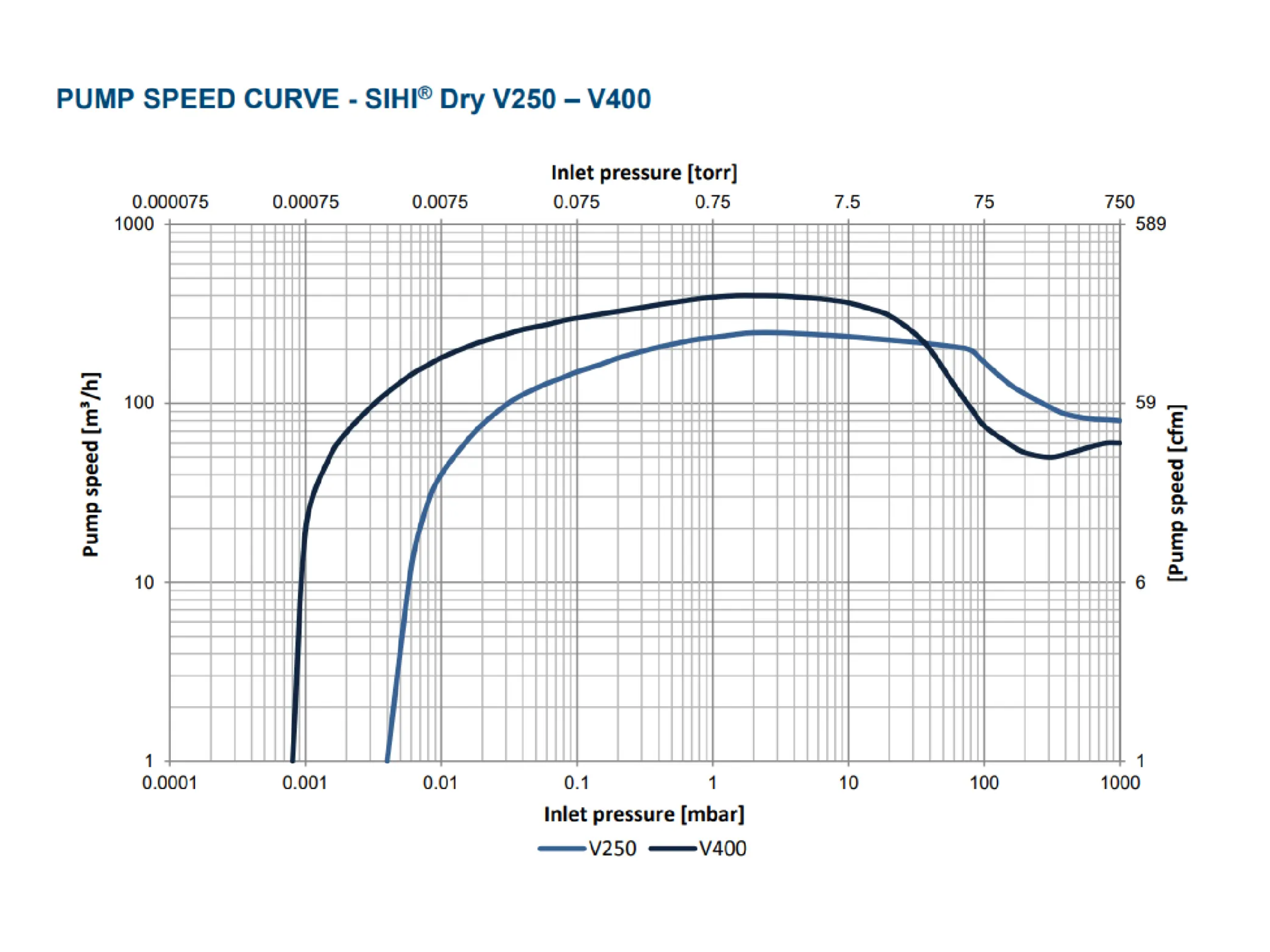

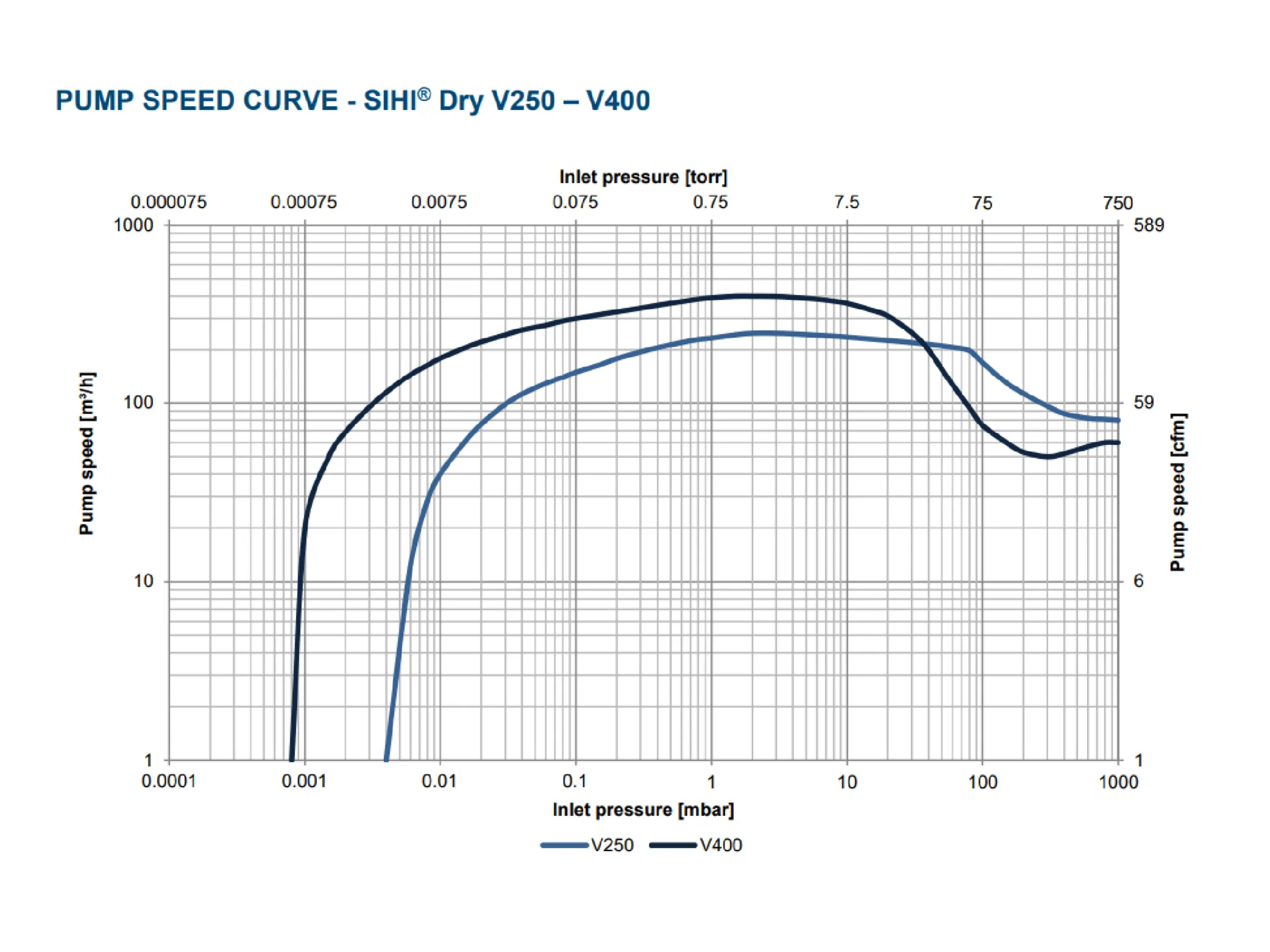

GD V-Version:

Perform maximum pumping speed already at atmospheric pressure

- Suction volume flow: up to 1500 m³/h

- Suction pressure: < 0.001 mbar

GD S-Version:

High pump speed at low suction pressure

- Suction volume flow: bis 1000 m³/h

- Suction pressure: < 0.005 mbar

The SIHI® Dry Compact Design Vacuum systems are engineered with a compact design that prioritizes user-friendly handling and connection. Additionally, the SIHI® Control provides advanced and fully-integrated control features:

- Autonomous supervision and control of all integrated actors and sensors

- Local control via HMI touch interface

- Condition monitoring options adaptable

CD V-Version:

Perform maximum pumping speed already at atmospheric pressure

- Suction volume flow: up to 1500 m³/h

- Suction pressure: < 0.001 mbar

CD S-Version:

High pump speed at low suction pressure

- Suction volume flow: bis 1000 m³/h

- Suction pressure: < 0.005 mbar

Industries/Markets:

Perform maximum pumping speed already at atmospheric pressure

Solar & Photovoltaic

Semi-conductor

Vacuum Induction Melting

Food & Beverage

Healthcare

Lighting

Aerospace

Electronics

Applications:

High pump speed at low suction pressure

Vacuum Coating

Crystal Pulling

Metallurgy Furnaces

Central Vacuum

Sterilization

Freeze-drying

Degassing

Product Transfer

At the heart of the SIHI® Dry design, you will find a focus on simple operation and long-term reliability. The vacuum pump is completely free from oil lubrication, does not require mechanical seals, and features wide internal clearances, which together enhance its robust nature and enable dry running.

Dry Running Vacuum Pumps

for Chemical & Pharmaceutical Applications

The SIHI® Dry Chemical PD vacuum systems can be used for all chemical applications where a robust, explosion proof and high reliable dry vacuum pump is required. The flexibility of the modular system allows it to be adapted to any process conditions. Thus, the innovative drive concept and its optional additional features, such as the regulation of the speed to meet the requirement of the system, offers the possibility to reduce the power absorption considerably.

SIHI® Dry fulfills the need for a resilient high-vacuum pump that can accommodate swiftly changing process conditions, encompassing potentially explosive, corrosive, and/or thermally sensitive media.

M and MI Series:

Features a cooling jacket that removes heat from the pumping chamber to keep the gas temperature low.

H Series:

Along with a cooling jacket, the SIHI Dry H H250 to H630 Series includes an internal spindle cooling.

The H750 to H1000 offers the same cooling jacket and internal spindle cooling but comes with a direct gas cooling feature. This opportunity allows the direct injection of cold gas into the compression room – with no effect to the suction capacity.

Benefits you can count on:

Enhanced reliability even in challenging process conditions, thanks to the prevention of particle and liquid carryover and safe handling of condensable, corrosive, or toxic mediums.

Improved availability through integrated condition monitoring that detects pre-failure signs and enables data logging.

Minimized downtime with self-draining, top-down flow and easy on-site servicing by your own staff.

Reduced total cost of ownership achieved by eliminating the need for lubrication and mechanical seals, resulting in low maintenance costs and an energy-efficient design.

Quiet – Less than 63 dB (A) for a comfortable working environment